The SHEQ Policy aims to ensure alignment to the Sarens mission and values, where ‘Dedication to Safety’ means ensuring that harm is not inflicted upon its employees, contractors, service providers, or the environment, Sarens assets, as well as members of the public affected by its operations, infrastructure and all operational activities within the scope of heavy lifting, special transport, assembly, disassembly and maintenance in industry and infrastructure.

Sarens management and all employees are committed to well-being and protection of human life, environmental duty of care, protection of assets and customer satisfaction by applying our Plan-Do-Check-Act (PDCA) cycle and our Code of Conduct in all Sarens activities.

Sarens has integrated safety, health, environment and quality requirements into all activities; more specifically in the Sarens Project Management Procedure (SPM) and care for preventive maintenance so that decisions made ensure the consideration of economic development, environmental quality, and social equity to continually improve performance and achieve stakeholder requirements.

Sarens will avoid harm to people and the environment while providing quality services to our customers

Sarens commitment to Safety, Health, Environment and Quality management is achieved through:

- Implementation of an integrated management system in accordance with ISO9001:2015, ISO14001:2015, ISO 45001:2018, and VCA-P 2017 /6.0.

-

Achieving compliance with applicable legislation and other requirements to which Sarens subscribes and in the absence of these, setting internal standards to meet the intent of this policy.

-

Addressing the needs and expectations of Sarens clients and stakeholders.

-

Setting SHEQ objectives goals and measuring our performance (KPI’s) against these with the objective of continual improvement.

-

Periodical risk-based medical surveillance for all Sarens employees, to monitor and manage occupational health risks inherently present in the nature of our business.

-

SHEQ training and safety-based behaviour training for all employees.

-

Ensuring that our suppliers and service suppliers meet and adhere to Sarens SHEQ requirements.

-

Promoting open communication with all stakeholders and sharing of our SHEQ knowledge.

-

Real accountability for all our managers and employees in performing and tracking our SHEQ goals and targets.

-

Design, construction and operation of our services in a safe, secure, efficient, and environmentally responsible manner.

-

Sarens is committed towards having global sustainability goals.

-

Sarens will develop a comprehensive ESG strategy that will provide a detailed program to tackle key elements around environmental, Sustainability and Social impact.

-

Sarens is fundamentally committed to building long-term, sustainable businesses, which will grow, provide employment, and generate economic benefit in an environmentally and socially responsible manner.

Policy into practice

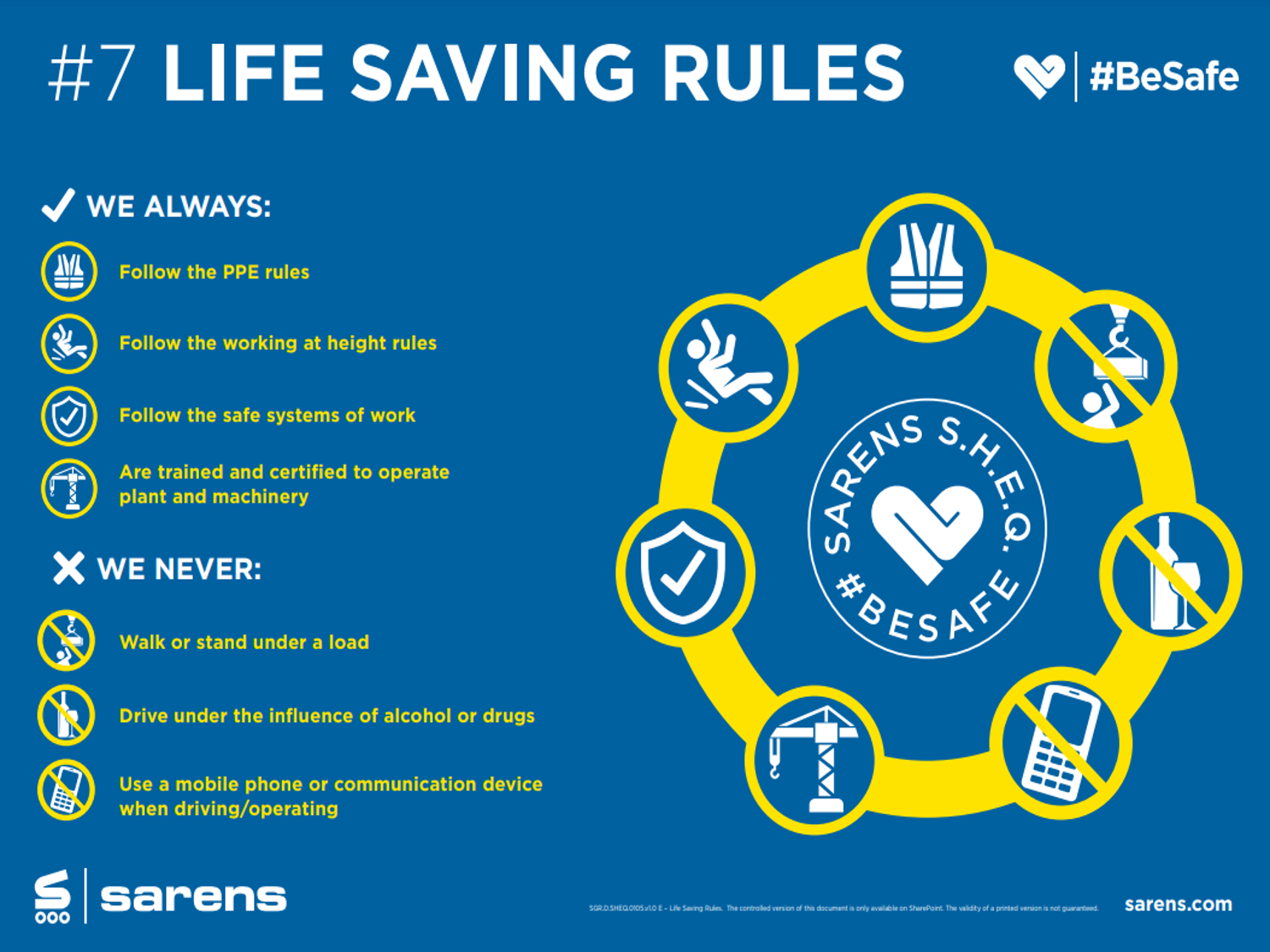

In order to put this policy into practice and avoid incidents and accidents, the Sarens 7 Life Saving Rules (LSR) are developed and implemented. All employees are expected to perform their job in accordance with this company philosophy and follow all applicable procedures and instructions including the Stop & Consult Procedure as a final Last-Minute Risk Assessment (LMRA) before commencement of work. Where necessary, the management will take measures by using our Consequence Management Procedure.

In addition to first using collective protection equipment, all employees have appropriate work wear and Personal Protection Equipment (PPE) that meets the highest standards in accordance with local legislation. The Management team shows clear responsibility and commitment to verify the effectiveness of our integrated SHEQ Management system by completing workplace inspections on a regular basis using the Prevention at Sarens (P@S) system.

The Sarens Management system is constantly improved by means of internal audits: local, cross and Group SHEQ, and external audits. A unique Sarens Year Action Plan for each Business Unit is followed up in the monthly management meetings and an annual management review so that any necessary remedial and prevention measures can promptly be taken to improve performance and efficiency.

In our strategy we will continue with the #BeSafe campaign with the use of Sarens Mascots and our weekly counter to ensure everybody is kept informed of our progress. The areas of concern for improvement will be reduction in equipment damages and further skills improvement in loading and lashing of our equipment for transportation. A new reporting tool has been introduced to SHEQ management and will be rolled out to all BU management in order to track and trace the usage of the P@S system.

Sarens has started to collate data to be able to form our carbon footprint. This will enable Sarens to reduce our impact on the environment in line with our new ESG strategy.

This policy statement is available on www.sarens.com and published in all our offices worldwide. It will be regularly reviewed (at least every year) by the Sarens Group Management to ensure that it remains in line with Sarens objectives and strategic priorities.

Wim Sarens

CHIEF EXECUTIVE OFFICER

March 2025

Read the Annual Reports here:

Sarens Annual SHEQ Report 2024

Sarens Annual SHEQ Report 2023

Sarens Annual SHEQ Report 2022

Sarens Annual SHEQ Report 2021

Sarens Annual SHEQ Report 2020

Sarens Home

Sarens Home