Sarens has an extensive experience in bridge installation and transport and has been a trusted partner for bridge installations across the Albert canal. Since 2018 Sarens has installed over 30 bridges on the Albert Canal.

In fact, one of the first bridge moves Sarens ever performed was in 1980 was the Haccourt Bridge on the Albert Canal, and it measured 90m long and weighed 1.400T. We have video footage of this historic bridge relocation, which can be viewed here.

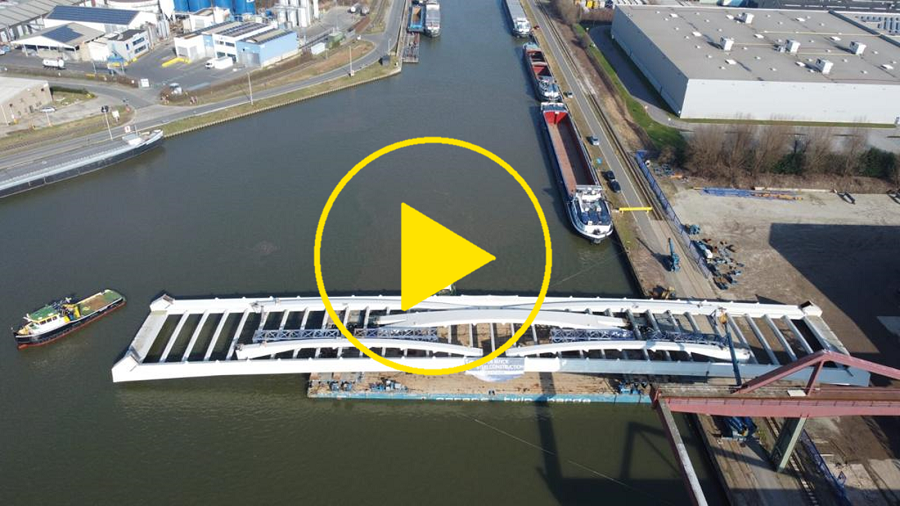

Recently Sarens was commissioned by our client Buyck to install 5 bridges on the Albert canal. The planning phase was crucial as the team had to address the low lying bridges and the width of the locks on the way during the transport of the bridges.

The equipment deployed were:

· Barges

· K24ST

· Four CS350 jacking systems

CS350 climbing system, the recently launched climbing system, combines fast operation with bottom-feeding jacking elements. The CS350 offers great advantages in possession work, where timing is important. It is one-of-a-kind system, custom-built solution, and developed 100% in-house, drawing on Sarens’ knowledge and experience in developing the CS1000 and CS5000 and inspired by a clarity of vision for what was possible. Due to ease of set-up and operation, as well as its ability to raise loads up to 6m without bracing, Sarens used the climbing system for installation of the bridges on-site.

Each bridge measured 128m in length and weighed 1100T. According to Project Manager, Peter Keyen, “Due to the outstanding length of the bridge we had to couple the tugs to the bridge instead of coupling them to the barge. A special permission was needed for the maritime transport of the bridge.” He added, “Our expertise in bridge installation, built up over many years spent listening to and understanding our clients' requirements and challenges, makes the project a routine for us but for the local residents and onlookers it is nothing less than a spectacle which makes us very proud of our achievements”.

Watch the #Howwedoit video of the project here!