In 2018, Sarens will unveil the new SGC 250 crane for a high-profile project on behalf of joint venture clients Bouygues Travaux Publics of France and Laing O'Rourke Construction of the UK. The nearly 4-year project, valued in excess of £20 million, involves the construction of a new nuclear power plant at Hinkley Point, Somerset, UK.

"Hinkley Point is an extremely prestigious project, not only in the UK and Europe, but also globally," says Sarens Project Manager Mark Rowlands. "The eyes of the world will be watching how Sarens performs."

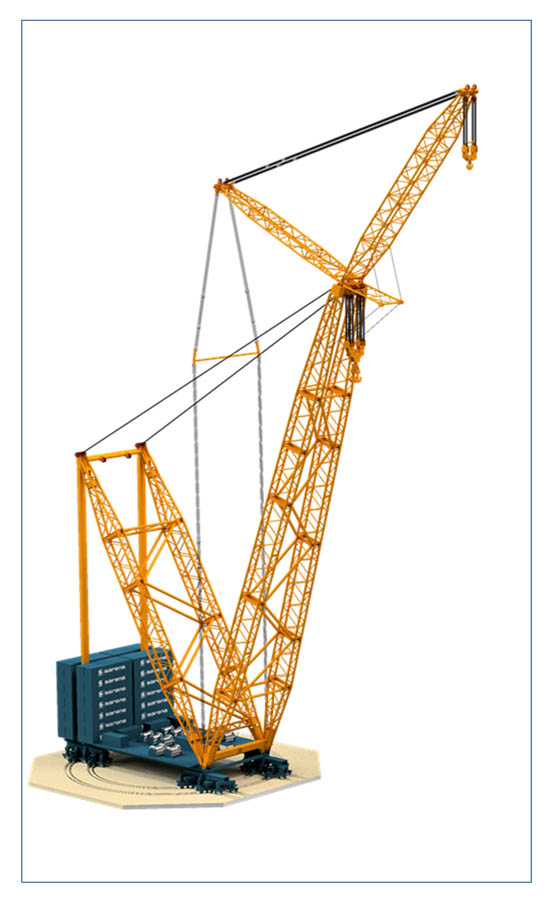

Sarens is bringing the specialized knowledge and financing to design, build, and operate such a large crane, which will soon be the largest SGC in the Sarens fleet. Thanks to six kilometres of rail laid on-site, the crane will also be able to travel between three different lift locations without the need for disassembly or re-assembly.

The SGC 250 will be mobilized overland from Gent to a nearby lay down yard before it is shuttled to the project site. An estimated 280 trucks will be required to deliver the entire SGC, though at the moment the narrow lanes leading to the site only allow 10 trucks per day. Plans are in the works for a purpose-built access road at the site, but a lot of planning will still need to go into all the logistics of delivery.

Once on site, the SGC 250 may need to perform lifts at night, using an anti-collision system. This would be done to minimize disruption during the day, when 52 tower cranes will be operating at the work site. The crew would need light to operate at night, but in this case the local bat population poses a special challenge. The team will need to find solutions that do not disturb the bats, which are a protected species.

With everything in place, the SGC 250 will begin performing various lifts ranging from 50t to 1.150t or more, and with radiuses of up to 165m. It will pick up and install prefab concrete elements, steel structures, and reactor equipment directly from each prefabrication position. A second crane, the CC 2800, will assist as a rigging crane.