Construction of the New Champlain Bridge represents one of North America's biggest worksites at the heart of Montreal's transportation network and vital to Canada and specifically Quebec's economic growth. The New Champlain Bridge Corridor Project involves replacement of the existing Champlain Bridge over the St Lawrence River. The existing structure is one of the busiest crossings in the country for about 40 to 60 million cars, trucks and buses a year, and is a critical passageway for the regional and Canadian economies. In terms of Canada-US trade, more than $20 billion worth cross-border goods pass through this trade corridor each year.

Sarens was roped in for this esteemed project by SSLC (Signature sur le Saint Laurent) which is a joint venture company between SNC Lavalin, Dragados, Flatiron and others. The task involved installation of 38 footings for the New Champlain Bridge over the Saint Lawrence river in Montreal, Quebec, Canada. The bridge will be made up of 74 footings, 38 of which will be prefabricated at the jetty, while the 36 other footings will be made by pouring concrete directly into foundations in the river bed. Each footing is 11 metres by 2 metres (or 9 X 9 X 2 metres) and comes with a pier starter, giving the overall assembly a height of up to 14 metres. The weight of a single footing ranges between 600-1000 tonne.

Since there were no Canadian vessels that could provide the complex services required for the project, Sarens offered a unique solution by designing and building a special equipment, the Floating Foundation Installer (FFI).

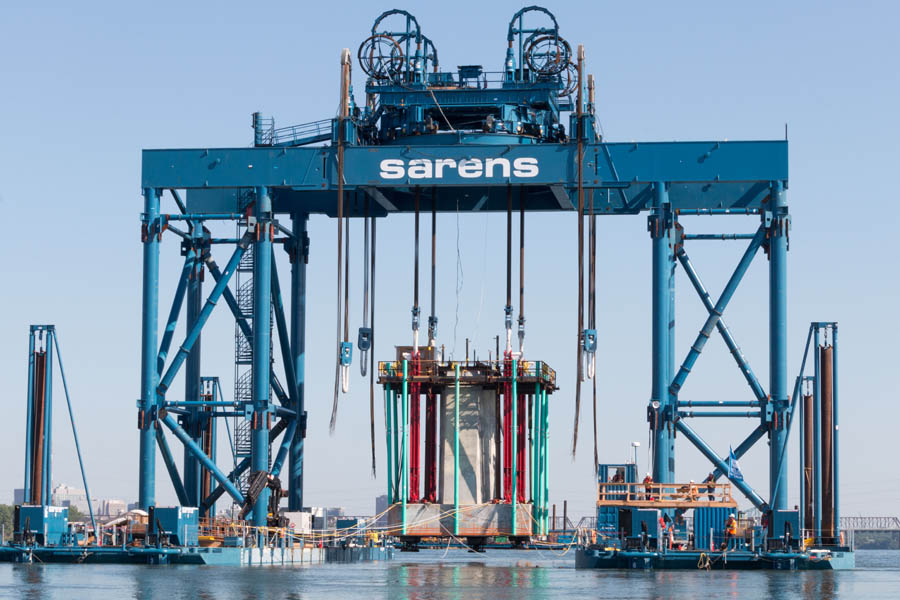

The Floating Foundation Installer (FFI)

The FFI was contemplated specifically for the New Champlain Bridge Project to transport 38 footing and initial pier section combinations from the jetty to their final location at the bottom of the Saint Lawrence River. The FFI is a Self-propelled catamaran that can lift, transport and install foundations by its own means. It is outfitted to operate in strong currents and to lift and transport parts that can weigh up to 1000 tonne. The lifting apparatus has a turntable, allowing for a 360-degree rotation of the parts.

The FFI consists of two SMB barges equipped with eight thrusters, sixteen winches, four spuds, two SMLT towers with gantry beams and rotation bogies and eight 450T Strand Jacks. The design is a combination of structural, maritime engineering in combination with hydraulic and electronic steering systems.

Installing the footings by the FFI.

The FFI was moored to the L'Île-des-Soeurs jetty, where it had to transport and place the 38 prefabricated footings to the river bed. The footings were first moved to the end of the jetty onto the loading dock, using the supertransporter, "Thor the Ant". The footing assembly was then tied on the FFI with steel cables. Once the assembly was secured, the FFI headed off to the designated location in the river. The river posed a challenge by creating a ccomplex environment owing to high current waters against the footing installation precision required. The FFI was then stabilized in final installation position with a powerful anchoring system comprising of eight anchor winches. The winch lines were operated to keep footing stable during final placing.

An advanced GPS system was used to position the FFI and the footing accurately. Additional adjustments were made using the FFI's turntable, which allowed workers to rotate the part when necessary. The part was lowered and put into place with a hydraulic cable and pulley system and hydraulic jacks. Final positioning checks were made with the GPS and precision prisms, located on each footing. The FFI then returned to the dock and repeated the entire operation with the next footing. Upon completion of the installation of the first footing, the Client responded, " From the early stages of the feasibility studies till the final design and construction, there has been a remarkable and close collaboration between SSLC team and Sarens team. All leading to the successful installation of the first footing today."

Sven Janssens, Sarens Operations Manager describes his experience with the project, stating that, "Sarens undertook a daunting technological and operational feat by flawlessly handling the installation of the footings for the notable Champlain Bridge Project. It is by far the most challenging project where I had the opportunity to be a part of at Sarens."